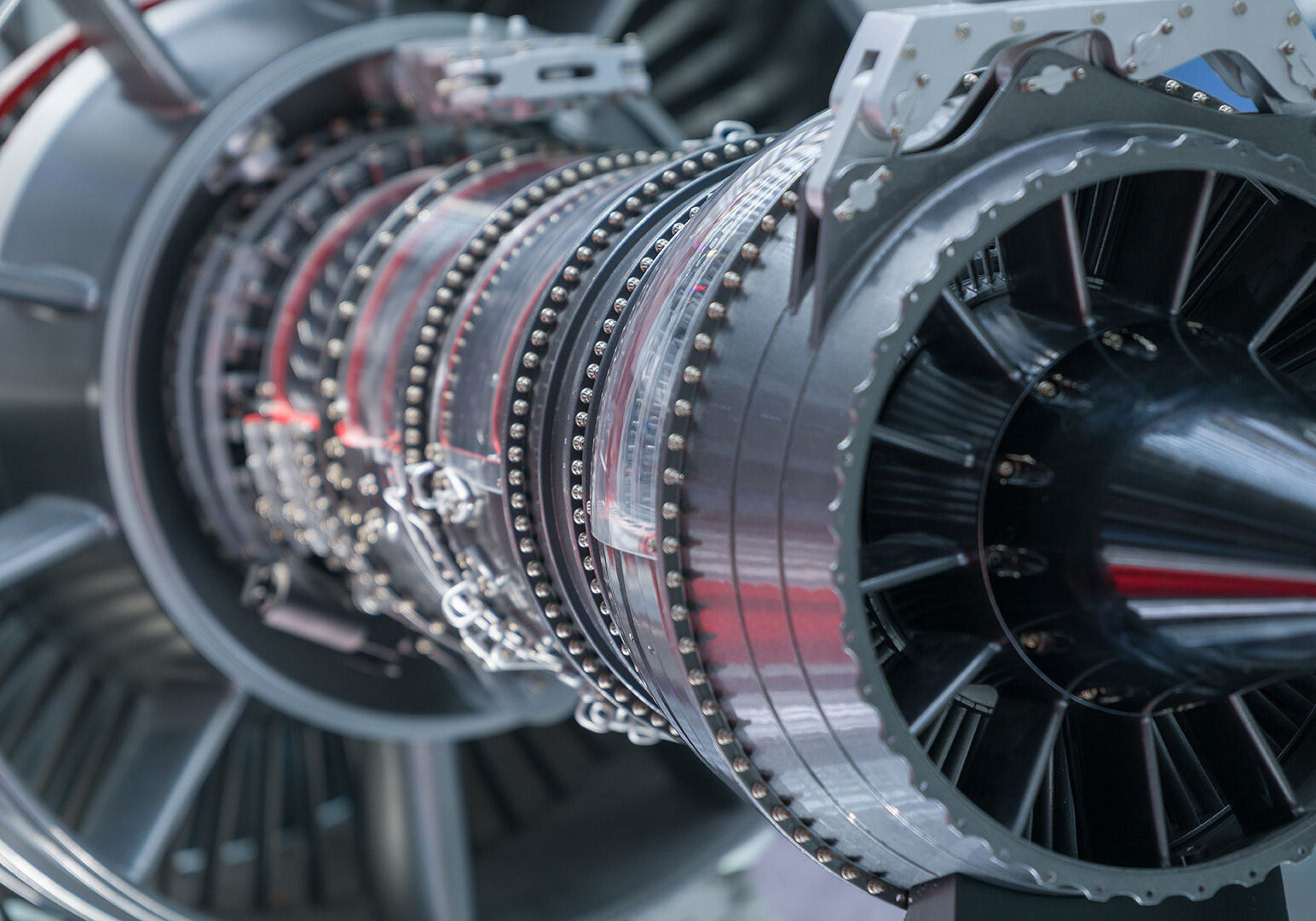

Extreme Duty Titanium Castings

for Aerospace

Titanium castings provide exceptional strength and performance properties for an industry that extends to theaters around the globe. For extreme environments at the highest altitudes – and to the bottom of the sea – FS Precision produces precision titanium castings to the exacting standards required for severe duty applications.

Titanium castings provide exceptional strength and performance properties for an industry that extends to theaters around the globe. For extreme environments at the highest altitudes – and to the bottom of the sea – FS Precision produces precision titanium castings to the exacting standards required for severe duty applications.

FS Precision incorporates very precise characteristics into its products in order to achieve the stringent performance requirements of the aerospace industry. An exceptional strength-to-weight ratio ensures titanium will withstand extreme forces – both static and cyclical – while remaining light weight. In addition, the naturally occurring corrosion resistance of titanium protects its mechanical properties against some of the harshest chemical environments to ensure functionality throughout an extended lifespan.

FS Precision has invested years of research and development to establish its AS9100 certified near-net casting procedures. Our disciplined six sigma manufacturing process controls ensure the aerospace industry is fully equipped to continue pushing the boundaries of technology from the sea to space.

Learn More

The article below discusses general design considerations for materials within the aerospace industry, followed by a discussion of titanium’s unique properties. It further discusses FS Precision’s cost-effective titanium investment casting process. Some current applications of near-net titanium castings in the Aerospace industry is also discussed.

Design Considerations for Aerospace

The aerospace industry is arguably at the forefront of development for extreme and innovative technologies. It is also one of the farthest reaching industries in the world, and its global applications in a variety of extreme environmental conditions demand the finest precision. Designers are faced with boundless volumes of specifications, manufacturing and inspection requirements, and quality standards – such as AMS, Nadcap, and AS9100, to name just a few. Engineering design for the aerospace industry is clearly as complex as it is critical, and must overcome numerous operating challenges.

For flight applications, these performance requirements typically manifest as load capacity and fatigue endurance of the aircraft, with an intense need to minimize weight. In fact, both static and fatigue strength are directly related to the overall weight of an aircraft and its component design. All other variables being equal, larger, heavier components typically provide greater strength than those which weigh less. Consequently, the process of minimizing weight can negatively impact strength and endurance.

To illustrate the fundamental design dilemma between strength and weight, refer to the basic aerodynamic flight Equation 3 below. For a more detailed discussion of this equation’s derivation, refer to aerospace castings.

[Eq. 3]

T = W/(L/D)

Where L equals lift, and D equals drag. Equation 1 illustrates the fact that any increase in weight (W) must consequently be balanced by an increase in thrust (T). Such an increase in thrust typically requires larger engines or components, and results in consequent higher stresses. This in turn may lead to heavier and stronger components to absorb the increased stresses, which in turn leads to increased weight. This stress-strength-weight cycle leads to the classic design dilemma in aircraft design: How to maximize strength while achieving acceptable weight limits.

Production costs notwithstanding, a larger heavier engine also comes with increased operating costs. While the exact operating costs may differ greatly across application platforms, a single pound of additional weight for a satellite application may cost between $10,000 and $15,000 in launch costs alone. While fuel costs may be significantly lower for sub-orbital flight, the penalties for excessive weight are still quite severe for typical aircraft.

The stress-strength-weight cycle referred to above becomes even more complicated when considering increased fatigue loading. The powerful engines sending aircraft into the sky produce an extreme amount of high magnitude cyclic thrust stresses, as well as the accompanying high frequency vibrations. These low cycle and high cycle stresses begin from the moment the engines are spooled up, and continue throughout flight. Any material a designer chooses must be able to withstand this continuous loading and unloading – stress cycling – with minimal or no loss of mechanical strength. It’s clear that the aerospace design engineer has no shortage of complicated choices to make during the material selection phase. Striking that perfect balance between overall weight and power, while still checking off the multitude of other program requirements is no minor undertaking.

And, the aerospace industry requirements is not limited merely to airborne projects. Ground and ocean based equipment are equally important, and involve equally challenging, albeit different design considerations.

Design Considerations for Sea and Land Based Systems

For land and ocean based applications, an additional primary consideration – beyond those of strength and weight – is corrosion resistance.

For land and ocean based applications, an additional primary consideration – beyond those of strength and weight – is corrosion resistance.

Nearly every program application has some degree of corrosion consideration; whether for a ground vehicle being deployed for long periods of time in harsh conditions, or an autonomous ocean vehicle exposed to corrosive seawater. The list of potential corrosive agents is almost limitless for the wide range of potential programs. Standard fuels and oils used in most vehicles may accelerate chemical corrosion, leading to compromised components. The risk of corrosion is compounded by the high loads and stresses which can further challenge a system’s long-term reliability.

The risk of component corrosion increases dramatically in the field of ocean based systems where the high concentrations of salt in the environment itself causes corrosive reactions with most metals. This reaction, known as REDuction-Oxidation – or the Redox Reaction – is triggered by a charge imbalance between the metallic atoms contacting the water and the ionized particles within the salt. In the RedOx reaction of titanium, a thin and impervious layer of inert titanium dioxide forms a protective shield on the surface of titanium components through a series of electron exchanges. See further details of this reaction in our article on how to prevent seawater corrosion.

For most metals, including untreated steel and aluminum, this oxide layer is extremely unstable and readily comes free. Think of a common layer of rust – or iron oxide – which is the typical resulting compound of the Redox reaction of iron. As this soft layer of oxide comes free, fresh metal is exposed and the Redox reaction continues, slowly scaling away material and weakening the metal component. This material degradation lowers the mechanical strength of the metal through several mechanisms, including development of stress corrosion cracks. Through repetitive and continuous Redox, the simple removal of enough iron material will compromise a component’s load handling capability. Eventually, this process opens the door for a complete component or system failure.

Unfortunately, this form of corrosion is hardly limited to ocean-based projects. Nearly any environment containing oxygen can potentially trigger the Redox reaction on any untreated aluminum or steel components. This means that any ground vehicle or component is susceptible to the harmful effects of material corrosion.

Consequently, design engineers must be vigilant to ensure that all critical components are designed to withstand corrosion, and to ensure that corrosive materials remain segregated whenever possible. For many applications, corrosion protection of aluminum or other alloys can be improved through the processes of anodizing or alodizing. These are chemical enhancement processes which add production time and cost to each component. One disadvantage of these surface enhancement processes is that they are just that: surface enhancements only. In the event of mechanical impact or other damage, surface corrosion protection might be inadvertently removed, thus allowing corrosion to gain a foothold inside the core material at the damage site.

While it is true that corrosion can be a critical consideration for sea and land based systems, basic material weight and strength also plays a critical role in systems designed for sea and land applications.

The Importance of Weight in Sea and Land Based Systems

Although the monetary impact of weight for sea and land-based applications is typically not as high as that for aerospace applications, ground based vehicles may also enjoy significant benefits from remaining lightweight. Road vehicles and equipment often require ease of handling in order to be most effective. Low weight provides significant improvements in the transportation across great distances for road vehicles and systems. This weight consideration for road vehicles, however, comes with similar side-effects as those discussed in our article on aerospace castings. Designers often must select which components may be manufactured from aluminum for its weight benefits, and which should be made from steel for its strength characteristics. As previously discussed, many systems which would otherwise benefit greatly from reduced weight are forced to use heavier steel in order to maintain stress limits.

Although the monetary impact of weight for sea and land-based applications is typically not as high as that for aerospace applications, ground based vehicles may also enjoy significant benefits from remaining lightweight. Road vehicles and equipment often require ease of handling in order to be most effective. Low weight provides significant improvements in the transportation across great distances for road vehicles and systems. This weight consideration for road vehicles, however, comes with similar side-effects as those discussed in our article on aerospace castings. Designers often must select which components may be manufactured from aluminum for its weight benefits, and which should be made from steel for its strength characteristics. As previously discussed, many systems which would otherwise benefit greatly from reduced weight are forced to use heavier steel in order to maintain stress limits.

Corrosion resistance and weight are only two primary considerations for material selection in sea and land based systems. As with Aerospace programs, an optimum material must be available that encompasses the best qualities of each – steel and aluminum – while also resisting corrosion.

Precision Geometry in Aerospace Applications

Regardless of the application, one universal constant is the relentless demand for quality and precision geometry. Achieving proper fit, maintaining critical sealing surfaces, and enabling efficient and flawless assembly procedures are an absolute necessity for any system.

These stringent requirements naturally drive designers to seek manufactured components that achieve tight tolerances and predictable material quality.

The traditional path to achieving such levels of precision is through extensive machining operations. Hogging out a solid block of material down to a single component with fine features and tight tolerances can be extremely costly, however. Both in the time it takes for the component to be completed, and the large amount of material that is converted into scrap metal shavings on a machine shop’s floor during the process. An alternative process must exist that can achieve comparable precision while reducing the time and material wastes associated with full scale precision machining.

The Advantages of Titanium

It’s plain from the information presented thus far that engineers face a plethora of design obstacles; many of which are mutually exclusive. Achieving minimum weight – while meeting stress loads and eliminating nearly all possibility for corrosion – is a daunting task. Add to this the cost factors that drive quality and precision tolerances, and one solution becomes readily apparent: FS Precision Tech cost-effective near-net titanium investment castings.

Titanium alloy is the natural choice to overcome these design challenges. Titanium boasts a strength which is twice that of aluminum, while it is substantially lighter than steel – nearly 40% lighter, in fact. This unique property – high strength to weight ratio – gives titanium alloys the ability to overcome those competing challenges of both strength and weight that dominate many design specifications.

The roots of titanium’s impressive strength to weight ratio may be tracked back to its atomic structure. A single titanium atom weighs in at 47.8 atomic mass units (amu) while an iron atom – a common material known for both its high strength and relatively high weight – weighs in only slightly more, at 55.8amu. At an atomic level, titanium weighs in at only 17% less than iron.

Iron, in its compound/elemental form, however, weighs approximately 80% more than titanium.

“How can that be,” you ask “if the atomic weights are so similar?”

The answer lies in titanium’s strong covalent bonds that hold its elemental crystal structures together. These bonds, coupled with the large distance between the atoms, allow titanium’s atoms to have more space between them. With 294 picometers (pm) between each atom, the majority of any single piece of titanium is actually unoccupied space. This explains why titanium is – at a macroscopic scale – so much lighter than steel alloys.

Despite the large amount of space between the atoms, titanium’s strong covalent bonds preserve an impressive amount of strength and grant titanium the label of a “transition metal.” At nearly twice the strength of aluminum and half the weight of steel, titanium is an ideal material to meet stress margins while simultaneously minimizing its weight.

Strength-to-weight is not the only point designers must consider. Even the most resilient and light-weight components are susceptible to the effects of harmful material corrosion. Once again, titanium is naturally prepared to address this point. As with traditional metals such as aluminum and steel, titanium also experiences redox reactions when exposed to oxygenating environments. The Redox of titanium typically forms a layer of titanium dioxide (TiO2) at the reaction surface. This “corrosion” of titanium, however, differs significantly from that of other metals. Titanium dioxide itself is extremely resilient to most forms of degradation. The thin layer of chemically inert TiO2 at the “corrosion” site is very tough and is difficult to remove. Because this inert layer remains intact, it offers a continuous surface barrier against corrosion for the entire lifespan of the component.

An added feature of titanium is that its chemically inert TiO2 layer is entirely self-regenerating and will constantly reappear after any mechanical damage occurs to expose the base material of the component. Scratching or chipping the titanium dioxide surface simply exposes pure titanium to the surrounding environment, allowing the same Redox reaction to occur once again – virtually instantaneously. This natural characteristic of titanium is a pivotal differentiator compared to aluminum and steel. Titanium alloys do not typically require any additional artificial surface enhancement operations. Its naturally occurring layer of protective oxide cannot – under normal operating conditions – be damaged to the point where chronic chemical corrosion occurs.

It becomes readily apparent that titanium is a nearly ideal option for many applications within the aerospace industry. Exceptional strength-to-weight ensures that useful load and operational performance can be achieved while simultaneously minimizing weight. Furthermore, titanium’s naturally occurring corrosion protection – in the form of its inert titanium dioxide outer layer – is in a class of its own above anodizing and other surface treatments. But how can these qualities of titanium best be delivered to the aerospace industry?

Precision Titanium Investment Castings for the aerospace Industry

In the past, the ideal properties of titanium have traditionally come with a steep price tag. The time and material required to produce wrought and machined titanium alloy often makes this material impractical for large scale use. In order to enable more widespread use of titanium, FSPT has invested years in development to perfect its repeatable and cost-effective systems for delivering titanium alloy components to the aerospace industry. These years of work have culminated in FSPT’s six sigma controlled near-net cast titanium. Our proven systems ensure that our customers receive the best buy to fly ratios while reducing material waste and excessive machining that can otherwise drive up the costs associated with fully machined wrought titanium applications.

FSPT’s cost-effective process begins with investment casting. We start with your design in all its complexity and create an exact wax copy through injection molding. From there, we coat the wax in a ceramic shell and then remove the wax, leaving behind a cavity in the shape of your complex component design. We then fill the shell with molten titanium. Once cooled, the ceramic shell is destroyed and removed from the component casting.

We then follow the casting process with a series of additional post-cast processes and inspections governed by AMS or ASTM specifications until your cast titanium component is ready for its final quality inspection and certification prior to shipment.

When designing components for the rigors of aerospace, two primary concerns that are likely in the forefront of the engineer’s mind are 1) component strength/fatigue and 2) tight tolerances. At FSPT, we address and resolve both concerns. Since titanium investment casting is the only thing we do, we do it very well. FSPT is AS9100 and NADCAP certified, and adheres to strict aerospace casting specifications of AMS 4991/4992, and AMS T-81915A.

After your titanium is separated from its ceramic shell, it is put under extreme temperature and pressure – up to 15,000 psi – in a process known as hot isostatic pressing (HIP), to collapse any internal voids which may have formed during casting. Following HIP, we have the capability to chemically mill your component, where the hard alpha-case layer generated by the high temperature conditions of casting is chemically removed. Our chemical milling is performed by our in-house certified chemical milling system.

In this “as cast” condition, we hold components to a typical 0.010” – 0.015” tolerance. While FSPT produces several net shape castings with final operating geometry, many of our castings are near net casting. The cast titanium is very close to final geometry, and we offer the option to process your components through a final machining process in order to achieve even greater precision if required. Throughout the entirety of its manufacturing processes, FSPT holds itself to extremely high quality standards.

Our process of near-net casting and machining ensures that no time or unnecessary expense is wasted in hogging out a solid block of titanium down to the final product. For many of our casting projects, a fully machined version may otherwise have begun as a 100-pound billet, and then been machined down to a finished geometry of five pounds or less. That’s money spent on wasted titanium and excessive machining operations! At FS Precision Tech, we like to say that “We put the air in your parts so that YOU don’t have to.”

FSPT Certified Quality and Proven Reliability

FSPT titanium is no newcomer to the aerospace industry. In fact, many of the biggest names in the business have recognized the unique potential of titanium’s technological benefit delivered via FSPT’s cost-effective investment casting technology.

FSPT titanium is no newcomer to the aerospace industry. In fact, many of the biggest names in the business have recognized the unique potential of titanium’s technological benefit delivered via FSPT’s cost-effective investment casting technology.

We’ve previously established that the design of airborne applications is full of complicated design requirements and standards. Extreme conditions coincide perfectly with the material selection considerations discussed earlier, where steel may handle the high loads and aluminum is light enough for extreme maneuvers. Neither of them alone, however, has the unique property of high strength-to-weight ratio.

Aluminum lacks the strength to withstand the extreme loading and fatigue experienced during high-G space launches and maneuvers; and steel alloys are simply too heavy to allow for the nimble maneuverability and performance required for the application. Fortunately, titanium alloys do offer a uniquely qualified solution!

High fatigue strength capacity? Titanium. Exceptional static loading capability? Titanium. Lightweight? Titanium. Certified quality? FS Precision Tech. Certified to the most stringent requirements of the automotive TS16949 and aerospace AS9100C standards.

High fatigue strength capacity? Titanium. Exceptional static loading capability? Titanium. Lightweight? Titanium. Certified quality? FS Precision Tech. Certified to the most stringent requirements of the automotive TS16949 and aerospace AS9100C standards.

These include global aerospace contractor leaders who have recognized the potential that titanium holds and have taken steps necessary to incorporate FSPT titanium investment castings into several of their advanced programs. Many of these advanced systems have seen years of successful service that have showcased titanium alloy’s applicability to the aerospace industry. With FSPT titanium on board, our customers rest assured knowing Nadcap compliant processes are producing top-quality components that will stand up to the rigors of extreme duty.

The potential applications, however, are nearly limitless with our cost-effective approach! Nearly any airborne vehicle can benefit from the high strength – low weight benefits of titanium. Eliminating excess weight in the engine compartment, fine-tuning aircraft center of gravity, or simply increasing useful load capacity. FSPT’s proven processes make titanium affordable and readily available to the aerospace industry, and opens countless doors for its eventual application.

Conclusion

FSPT appreciates the enormous burden facing designers within the aerospace industry. Our net shape and near-net precision titanium investment castings incorporate superb fatigue and load strength while simultaneously resisting virtually all forms of chemical corrosion. These qualities are delivered via FSPT’s certified and cost-effective investment casting processes to ensure unyielding reliability for our customers. Contact us and we’ll work with your team from beginning to end to provide exceptional titanium castings through our high-quality, six sigma processes.